1 2 r test location hardness|hardness test machine : purchasing In the macro range (conventional hardness range), tests are performed using large test loads ≥ 5 kgf, which also lead to correspondingly large hardness indentations on the test pieces. .

WEB31 de jul. de 2023 · A trajetória de NaBrisa começou cedo, com uma paixão fora do comum pela arte. Em entrevista à Privacy, a artista revelou que desde pequena, ela já .

{plog:ftitle_list}

Resultado da Cidade: Tanabi-SP Data Falecimento: 03/02/2024 Data Sepultamento: 04/02/2024 Hora Sepultamento: 10:00 Hrs. ROBERTO APARECIDO MORATO. 64 Anos . “Obrigado a Funerária Central pelo atendimento e atenção deste momento de sofrimento em que perdemos esse menino tão .

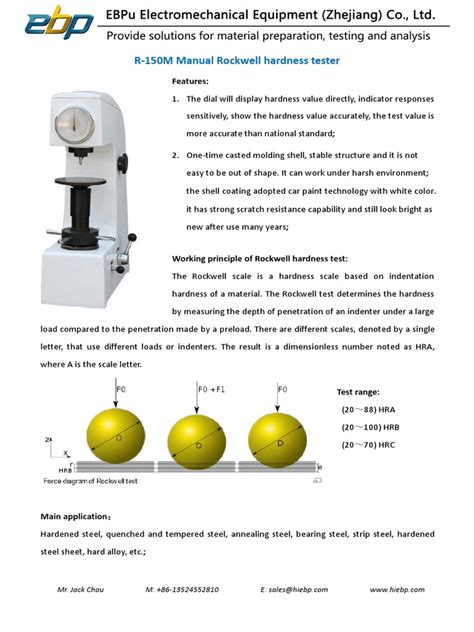

Regular Rockwell Testing. In regular Rockwell testing the minor load is always 10 kgf (kilograms of force). The major load can be any of the following loads: 60 kgf, 100 kgf or 150 kgf. No .1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. .According to ISO 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to . There are two types of Rockwell tests: • Regular Rockwell: the minor load is 10 kilograms of force (kgf) and the major load is 60, 100 or 150 kgf. • Superficial Rockwell: the .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. .In the macro range (conventional hardness range), tests are performed using large test loads ≥ 5 kgf, which also lead to correspondingly large hardness indentations on the test pieces. .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). F/D 2 ratio: 30,15,10,5,2.5,1.25,1 According to the engineering regulations, the ratio of F/D 2 is 30, 10 and 2.5, which are selected according to the material hardness and sample thickness. See various standards and test .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

Figure C.2 Test surface of the Rockwell hardness SRMs . average of six specific test block locations as illustrated in Figure C.1... 87 Table C.2: Hypothetical certified hardness values for specific test block locations. The x - y coordinate system is such that location x = 0, y = 0 is at the block center (NIST .M 1/ 4in ball 100 P 1/ 4in ball 150 R 1/ 2in ball 60 S 1/ 2in ball 100 V 1/ 2in ball 150 Table 1: Regular Rockwell scales. * Two scales- cabide and steel. d Scale Symbol Penetrator Load in Kilograms- Force 15 N N Brale 15 30 N N Brale 30 45 N N Brale 45 15 T 1/ 16 in ball 15 30 T / 16 in ball 30 45 T / in ball 45 15 W / 8 in ball 15 30 W / in .

test force. 3.1.7 Rockwell hardness machine a machine capable of performing a Rockwell hardness test and/or a Rockwell super-Þcial hardness test and displaying the resulting Rockwell hardness number. 3.1.7.1 Rockwell hardness testing machine a Rockwell hardness machine used for general testing purposes.preliminary and total test forces. 5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .3.1.6 Brinell hardness scale—a designation that identifies the specific combination of ball diameter and applied force used to perform the Brinell hardness test. 3.1.7 Brinell hardness testing machine—a Brinell hardness machine used for general testing purposes. 3.1.8 Brinell hardness standardizing machine—a Brinell

The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide).In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as . The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0)

Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness. . 1. Mohs hardness test kit. The Mohs hardness test kit is a scratch-testing kit with all the minerals in the Mohs Hardness Scale except diamond. Why? Diamond is expensive and needs mounting on a handle since . The Rockwell hardness test is the most commonly used hardness test in the industry due to its simplicity and accuracy. Brinell Hardness Test: This test measures the diameter of an indentation made on the surface .

1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .1 x R-0622-C Trace Hardness Buffer, 2 oz, DB 1 x R-0623-C Trace Hardness Reagent, 2 oz, DB TO ORDER REPLACEMENT PARTS AND REAGENTS CALL TOLL-FREE 800-TEST KIT (800-837-8548). . Hardness Test 1. Rinse and fill25 mL sample tube (#9198B) to 25 mL mark with water to be tested. 2. Add 5 drops R-0622 Trace Hardness Buffer. Swirl to mix.R-0012-C Reagent : R-0010-C Reagent : R-0011L-C Reagent : K-2005C Test Kit : K-2006C Test Kit : S-1403 Test Strips : Number of Tests - - - 9 : 8 : 7 : Testing Parameters : 2 oz Replacement Hardness Reagent for Professional & Residential Taylor(R) Test Kits : 2 oz Replacement Calcium Buffer Reagent for Professional & Residential Taylor(R) Test Kits When the Brinell hardness (HB) exceeds 450 or the sample is too small, the Rockwell hardness test is used instead. This test involves pressing a diamond cone with a 120° top angle or a steel ball (1.59mm or 3.18mm in diameter) into the material’s surface under a specific load. The hardness is then calculated based on the depth of the .

testing dc current voltage drop electric motors

Certaincommercial. entities, equipment, ormaterials. may. be. identifiedin. this. document. in. order. todescribe. anexperimentalprocedure. or. concept. adequately .Hardness Reagent (25 mL sample, 1 drop = 2 ppm hardness as CaCO₃) Documents; Shelf Life Concerns; More info . Documents; Shelf Life Concerns . whether they are liquids, powders, crystals, tablets, or test-strip pads. If kept dry, powders and crystals are very stable; acids are also long lived. . Location. Taylor Water Technologies LLC 31 .Cleaning of the polished test block surface is often required in normal usage but must not alter the hardness or quality of the polished test surface. A4.1.2 Test blocks that were standardized by a laboratory accredited in accordance with A4.2.1 to Test Methods E92 or Test Method E384 prior to the release of this edition of Test Methods E92 may .

4.3 Rockwell hardness testing at a specific location on a part . 5.1.2 Indenters for the Rockwell hardness test include a diamond spheroconical indenter and tungsten carbide ball indenters of specified diameters. 5.1.2.1 Steel indenter balls may be used only for testing thinTest; Match; Q-Chat; Get a hint. 7 Properties Used to Identify Minerals. 1. Color 2. Luster 3. Streak 4. Cleavage / Fracture 5. Hardness 6. . (Hardness) Scale 1- 10 Talc = 1 Diamond = 10. Density > the measure of how much matter is within a given space > Mass/Volume = (Density) (units = g/cubic centimeter) (D = g/ml)

The location for this test is select in the high magnification. A small diamond penetrator is then loaded with a predetermined load ranging fm 25g to 3000g. . Column I Column II P. Charpy test 1. Fluidity Q. Knoop test 2. Micro hardness R. Spiral test 3. Formability S. Cupping test 4. Toughness 5. Permeability (a) P - 4, Q - 5, R - 3, S – 2 . In scientific terms, water hardness is generally the amount of dissolved calcium and magnesium in water. But in layman's terms, you may notice water hardness when your hands still feel slimy after washing with soap and water, or when your drinking glasses at home become less than crystal clear. Learn a lot more about water hardness on the Water Science .

what is a hardness test

rockwell hardness test pdf

industrial hardness testing

webDie Kreuzworträtsel-Hilfe von buchstaben.com wird ständig durch Vorschläge von Besuchern ausgebaut. Sie können sich gerne daran beteiligen und hier neue Vorschläge z.B. zur Umschreibung Gerade Zahl beim Roulette einsenden. Momentan verfügen wir über 1 Millionen Lösungen zu über 400.000 Begriffen.

1 2 r test location hardness|hardness test machine